News

Donghua University has developed a lightweight, high-stability sound-absorbing material

2021-12-31

With the development of the transportation industry, traffic noise pollution has become increasingly serious, posing a potential threat to global economy, ecological environment, and human health. Many studies have used fibrous materials as core components of noise absorbers due to their porous structures and bending channels that enhance sound wave friction and dissipation. However, traditional fiber noise reduction materials have difficulty achieving high absorption performance for low-frequency noise, which is easily generated by vehicles, due to inherent limitations such as large fiber diameter and low porosity; increasing the thickness or density of fibrous materials will increase material weight and energy consumption, contradicting the concept of green and low-carbon; and commonly used polymer noise reduction materials have poor heat resistance, which not only easily leads to material decomposition and failure, but may also cause safety problems.

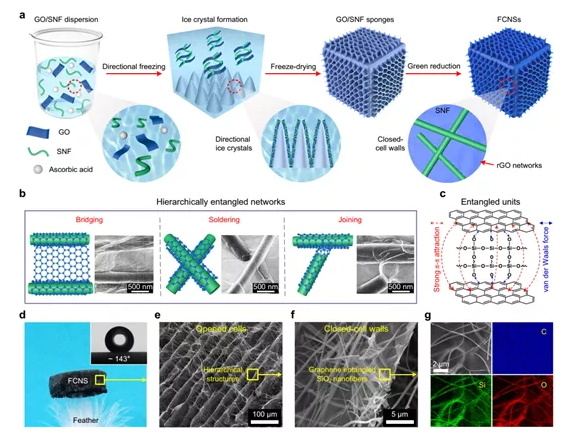

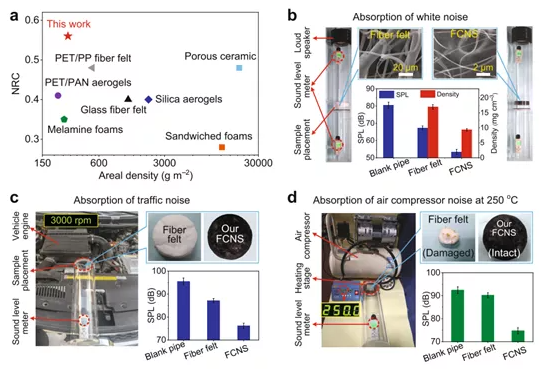

To address these issues, Academician Jianyong Yu's team at Donghua University proposed a method to prepare flexible ceramic nanofibrous sponges (FCNSs) with a unique hierarchical entangled structure composed of flexible SiO2 nanofibers (SNFs) and reduced graphene oxide (rGO) by combining directional freeze-drying technology and ascorbic acid reduction. To meet the requirements of traffic sound absorption materials for noise reduction performance, structural stability, and heat resistance, researchers selected flexible SNFs with good thermal stability as the basis for constructing the fiber framework structure; at the same time, flexible two-dimensional GO nanosheets were selected as adhesives and macro-pore blockers to establish effective entanglement between SNFs and block the pores of the fiber cavity walls; finally, a layered assembly structure was designed to achieve multiple dissipation of broadband sound waves. Unlike previous methods for preparing noise reduction materials, this manufacturing process combines the simple preparation of SNFs with the flexibility of directional freeze-drying technology, making the preparation of FCNSs easy and the structure adjustable.

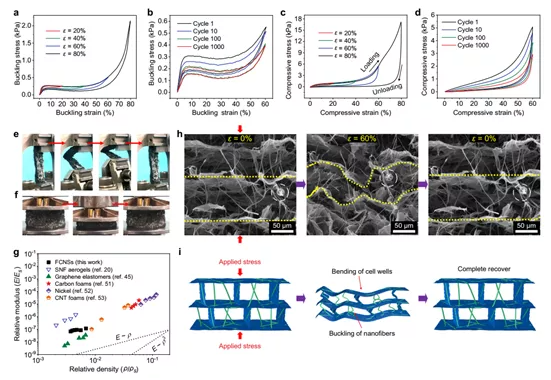

The mechanical properties of FCNSs are closely related to the content of SNFs and GO. Researchers found that FCNS70 (SNF:GO content ratio of 10:7) can have the required structural stability. The unique entangled structure gives FCNS excellent buckling performance, capable of withstanding large buckling deformation (80%) without fracture. FCNS70 also exhibits good cyclic buckling performance, retaining more than 70% of its initial maximum stress after 1000 cycles of buckling. In addition, FCNSs exhibit the required compressive fatigue resistance; under large strain (60%), the plastic deformation of FCNS70 is only 4.3% after 1000 compressions. Furthermore, FCNSs combine the structural characteristics of polymer materials and the high-temperature resistance of ceramics, exhibiting stable viscoelasticity and superelasticity at different environmental temperatures.

Researchers used the Johnson-Champoux-Allard model to guide and optimize the design of FCNSs, explored the influence of acoustic parameters on the sound absorption performance of FCNSs, and then further conducted feedback design on the structural parameters of FCNSs to achieve broadband noise absorption. A layered structure in the thickness direction of FCNS was further constructed, effectively enhancing the multi-level reflection path of sound waves inside the material, thereby successfully increasing sound energy dissipation, exhibiting high noise absorption (NRC of 0.56) and ultralight characteristics (280.8 g/m2).

This method breaks the bottleneck of low-frequency absorption of traditional noise absorbers and provides a broader approach for the development of high-efficiency noise reduction materials. The relevant research was published in Nature Communications under the title “Flexible ceramic nanofibrous sponges with hierarchically entangled graphene networks enable noise absorption”. (From Textile Guide)

Previous Page

RELATED INFORMATION